Introduction

In this video, we present a technical introduction to the Roll Forging Machine, focusing on its main structural components and their respective functions. As a critical piece of forging equipment, the roll forging machine plays a decisive role in billet preparation for downstream forging processes.

Main Structural Components

•Machine Frame (Base and Housing) – provides rigidity and stability for continuous operation.

•Rollers (Forging Dies) – specially designed and heat-treated to shape billets with precision and durability.

•Transmission and Drive System – ensures synchronized rotation and consistent rolling pressure.

•Feeding and Guiding System – positions the billet accurately for uniform forming.

•Control System – integrates automation, monitoring, and adjustment for different billet sizes.

•Safety Protection – safeguards operators and equipment during high-load operation.

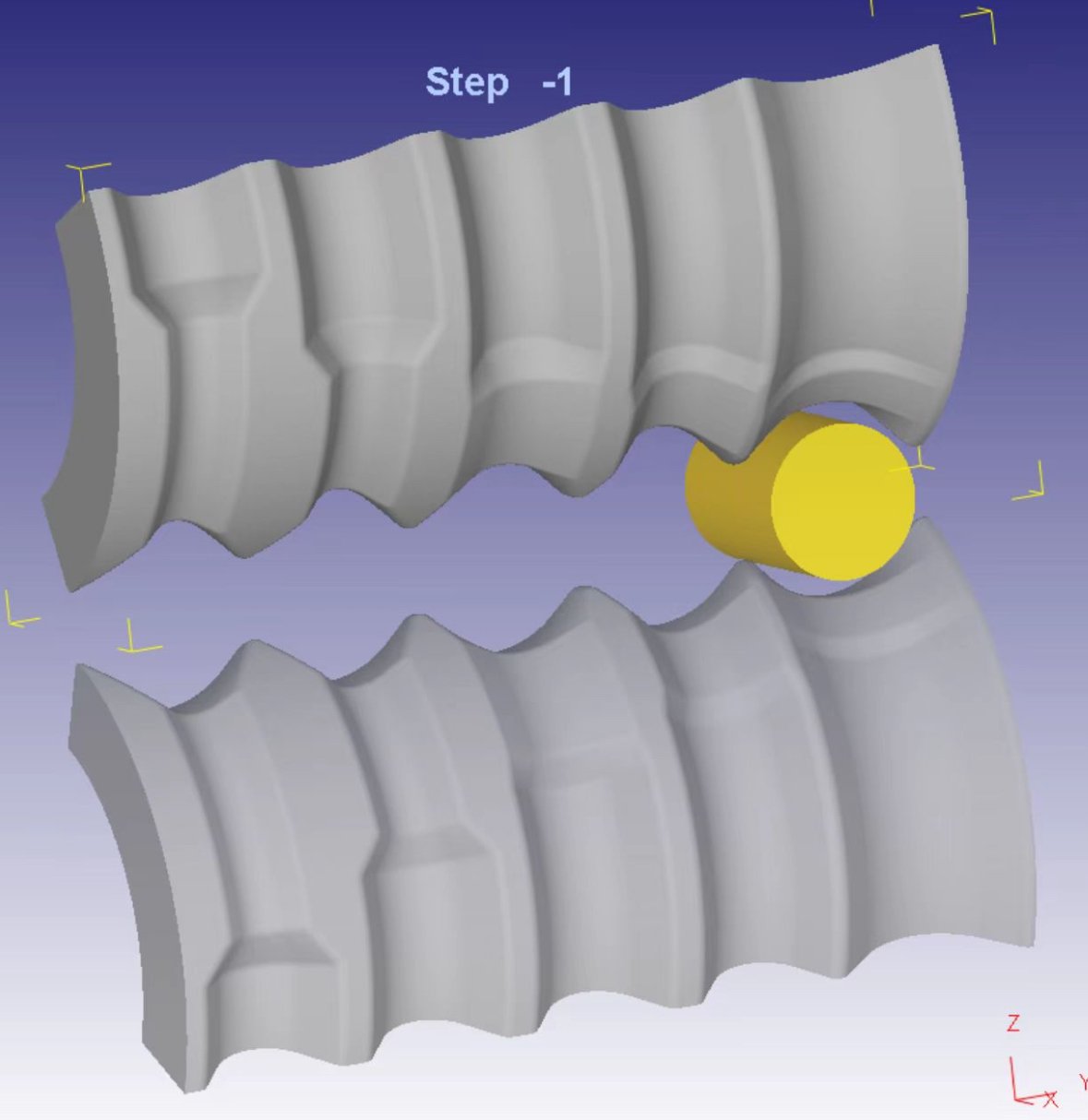

What is the working principle of automation roll forging machine?

The upper and lower forging rolls rotate in opposite directions synchronously, driving the sector dies to repeatedly bite and compress the round billet. While the billet is flattened in the height direction, it simultaneously elongates along the length, enabling rapid stretching and sizing to form a dense and dimensionally consistent preform or final forging

Applicable Processes

- Section reduction operations such as elongation of shaft parts and flattening of slabs

- Preforming operations before die forging

- One-step forming of lightweight long rods and components with irregular cross-sections

Core Values

- High material utilization – Elongation forming reduces machining allowance, saving up to 30%.

- Outstanding efficiency – Multi-pass rolling enables continuous production, with output 2–3 times higher than traditional hammer forging.

- Excellent consistency – Automated feeding and closed-loop control ensure dimensional stability and smooth die forging fit.

- Cost control – Labor-saving and energy-efficient, with long equipment and die life, significantly reducing overall production costs.