Roll Forging Machine | Cross Wedge Rolling Machine

Manufacturer Of

Automatic Forging Machine

Tailored Solution For Metal Preforming

High Efficiency and Maximize Savings.

Making your budge go further

Rapid preforming of metal billet, maximize output, and long lifespan of mold.

Precision forging in every workpiece with consistency shape, and simplifies the following forge operations.

Streamlined forging solution. Invest in automatic forging machine once, and lasting benefits for years

What is Metal Preforming?

Traditional Preformed By Air Hammers

Automation Roll Forging Now

Are you suffering from the same headache issues? Material waste and excessive operating costs.

Savings on your forging works.

Simplify your forging process with high speed

Inconsistent Metal Shape

High Labor Cost

Material Wastes

Short Mold Lifespan

Consistency Metal Preforming

Automation Manipulator

Optimize Cost & Save Budget

Long Lifespan of Mold

Product & Services

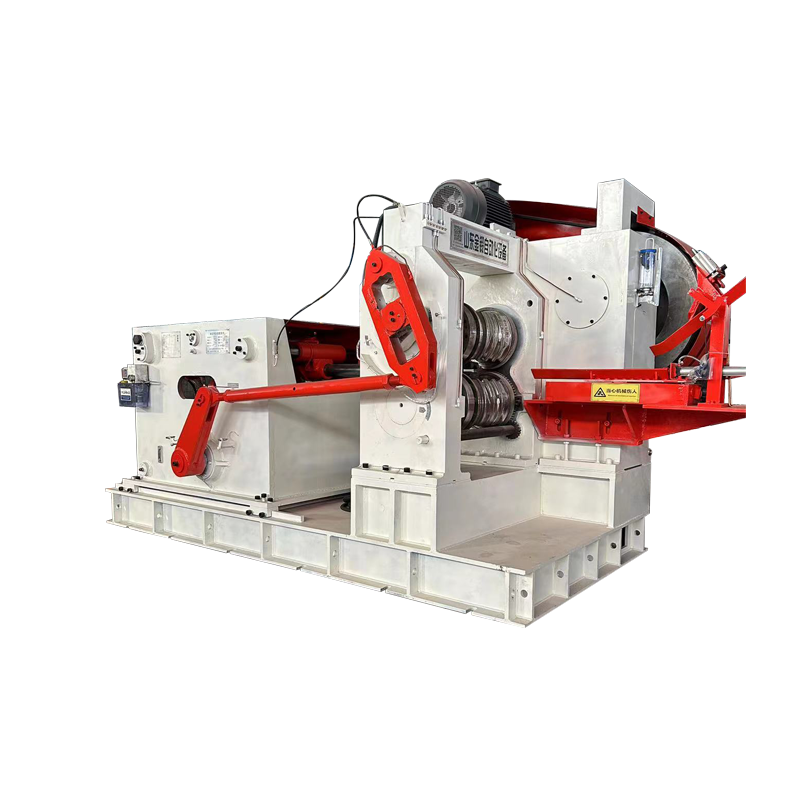

Universal Metal Preforming Roll Forging Machine

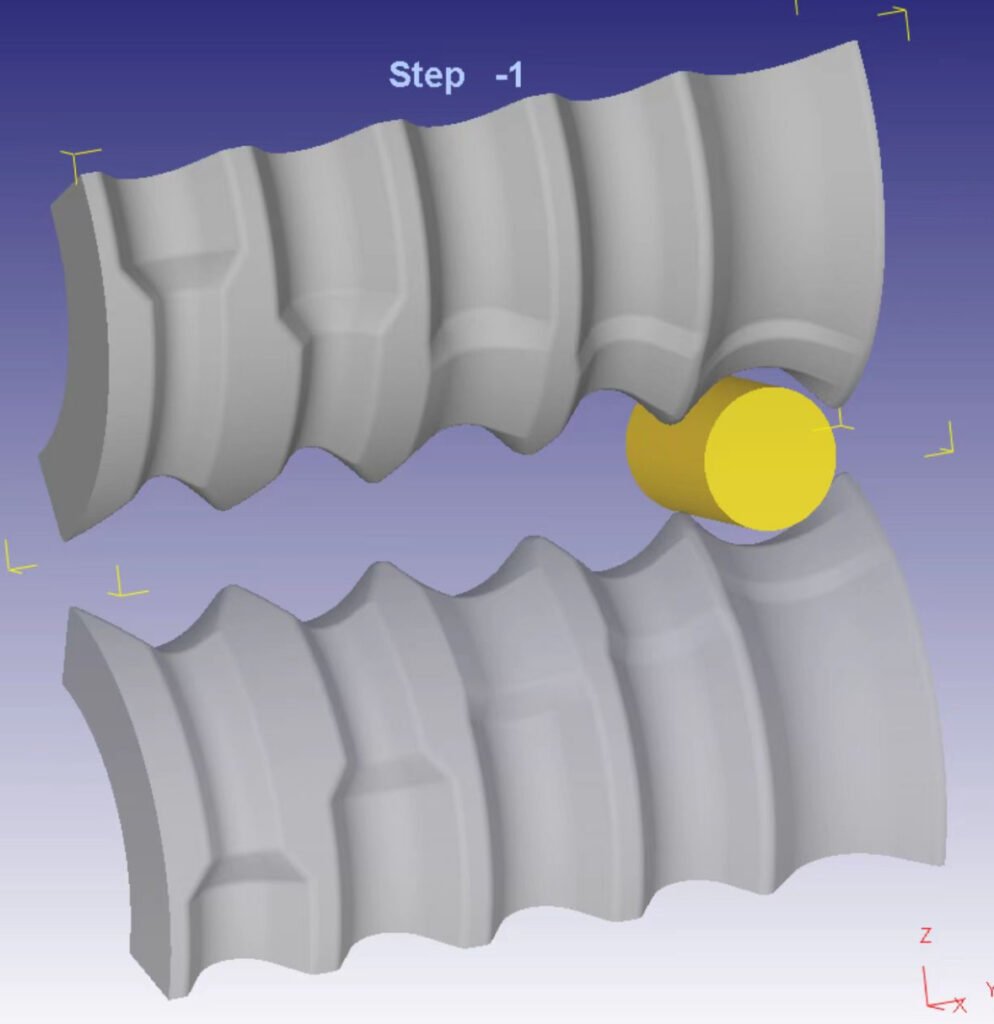

Roll forging machine (Reduce Roller) is primarily designed for the elongation and preforming of arm-shaped or shaft-type metals, transitioning the diameter from thicker to thinner

Why Upgrade to Automation Forging Line?

Traditional Forging Line

Automation Forging Linee

Integrates robotic systems for consistent quality, minimized waste, and high efficiency.

Rely on manual labor and leading to inconsistent quality and slower production.

High labor demands

Variable quality output

Excessive material waste

Limited production speed

Precision and consistency

Optimized material usage

Accelerated production rate

Reduced operating costs

Application Range

Make Your Metal Pre-forming Easier & More Effective

Control Arm

Auto Gear Shaft

Auto Camshaft

Auto Connecting Rod

Lifting Riggings

Lifting Hook

Selector Fork

Tie Riggings

Hardware Tools

Suspension Arm

Auto Suspension Parts

Auto Steering Knuckle

Motorcycle Crankshaft

Bicycle Crank

Crankshaft of Textile Machine

Auto Control Arm

Video Gallery

How The Machine Works

Ready to take your forging to the next level? It’s time to act and see how our technology & forging machines can help your business grow.

Forging of Auto Front axles

Integrated automation forging line of auto/truck forging line, taking you out of the heavy works

Forging of Auto Front axles

This video takes you through each precise step of forged bucket teeth production.

Automation Pre-Forming

Reduce roller and cross wedge rolling machine is the ideal solution for metal pre-forming

Technical Insights

Our Answers to Forging Queries

We QLM understand your forging challenges. Dive into our frequently asked questions to discover how we cater to your specific needs

While air hammers rely on pneumatic power to deliver force, forging roll machines utilize precision-engineered rollers to shape metal, ensuring consistent results and finer detail in forging

The manipulator automates material feeding and handling, reducing manual intervention. This not only saves labor costs but also boosts production efficiency by ensuring continuous, uninterrupted operations.

Cross wedge rolling machines offer controlled deformation, ensuring uniform material distribution. This results in precise, consistent shapes, minimizing defects and waste

Just image by using the old method of air hammer, you might be happy to see the daily output of 500pcs. With automation roll forging tech, you're looking at a leap of 1500-2000 pieces daily. This isn't just an upgrade; it's a complete transformation of how you operate, bringing you to the front of competitors in the forging industry.

Picture this - traditionally, shaping a billet eats up 5kg of your precious material. Now, enter our roll forging machine: that number drops to just 4.5kg. It's not just a saving; it's a revelation in material efficiency. With our technology, you're not just cutting back on waste; you're turning what used to be excess into extra profit. Imagine the impact over hundreds, thousands of billets. It's not just about doing more with less; it's about redefining efficiency in your forging operations

Voice of Trust From Partners

Our commitment to excellence resonates with our partners. Watch the trial running at customer’s site, who experienced the excellent service of QLM team.

We pride ourselves on our commitment to quality, service and innovation.

Let’s start forging a lasting friendship together

Reliability, precision, and efficiency.

Partner with QLM for forging solutions, we are your

trustable partner in forging engineering and technology.