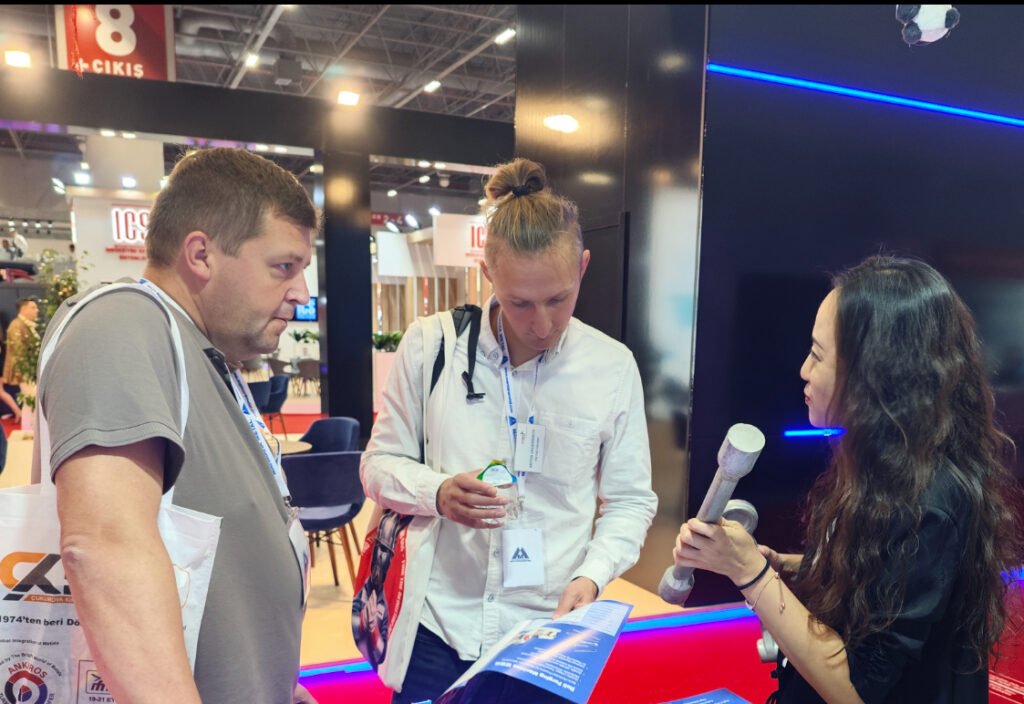

We want to thank all our friends and visitors for forging the connections. Our automatic forging equipment has been successfully showcased – Roll Forging Machines and Cross Wedge Rolling Machines

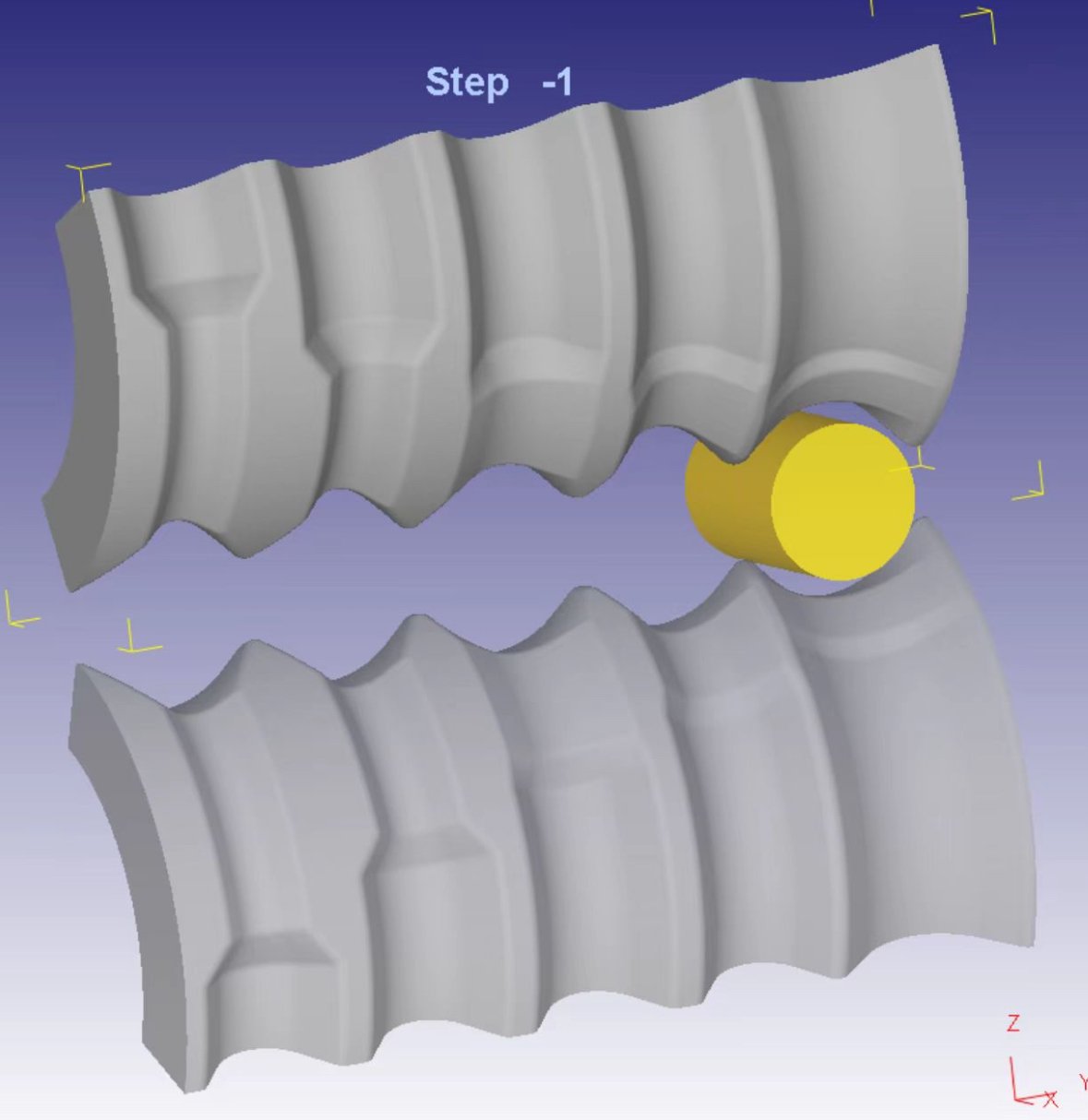

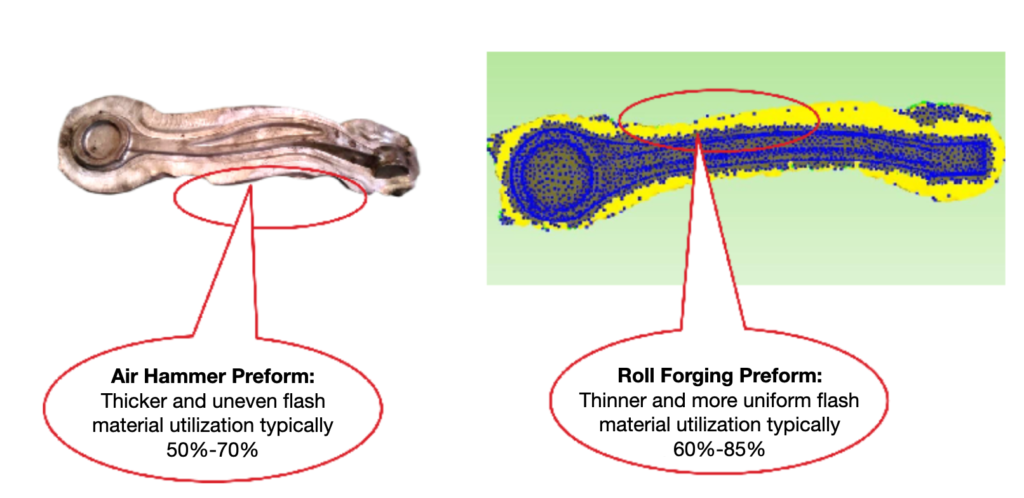

We understand the challenges you face and work with you to find solutions that enhance your production efficiency. The traditional way of metal preform is by using air hammer, which has limitation in many aspects,

Material Utilization Rate Overview:

- Straight arm/bent arm/stabilizer bar material utilization: 75%-85%

- U-shaped arm material utilization: 70%-80%

- Triangle arm material utilization: 58%-70%

- Steering knuckle material utilization: 65%-75%

(Material utilization rates vary based on product structure)

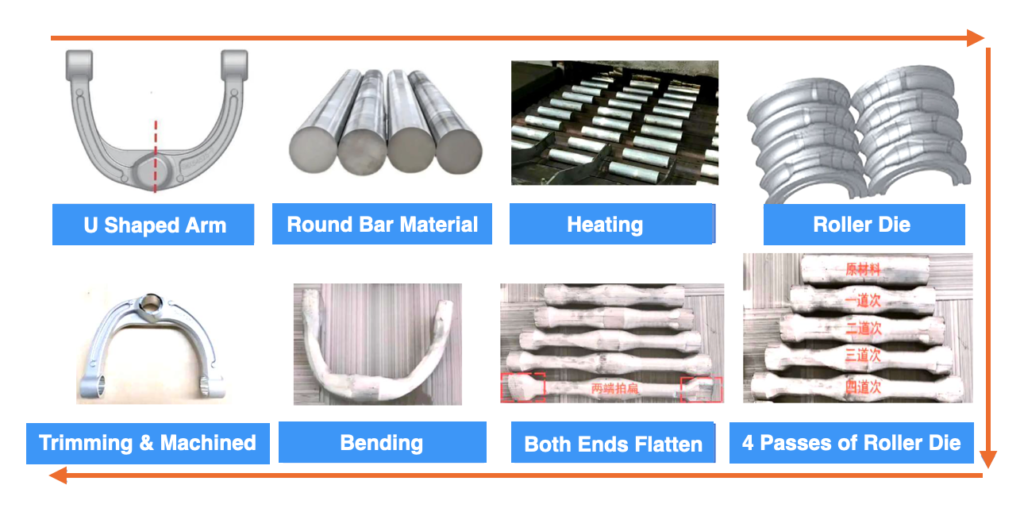

Our machine application range:

Suspension control arms, connecting rods, lifting lugs, rigging components, turnbuckles, safety locks, rear suspension control rods, transmission input/output shafts, bucket teeth, meat hooks, wrenches, femoral heads, surgical scalpels, camshafts, shift forks, steering knuckles

What we offer visible is qualified equipment and professional service. The most important thing is often invisible: our 15 years of forging experience. The production skills and insights that help you navigate the complexities of forging. By sharing this expertise, we enable you to avoid common pitfalls, minimize losses, and save production costs.

For more details, please call Technical Supports 0086 18954445568, 24/7 available.