Description

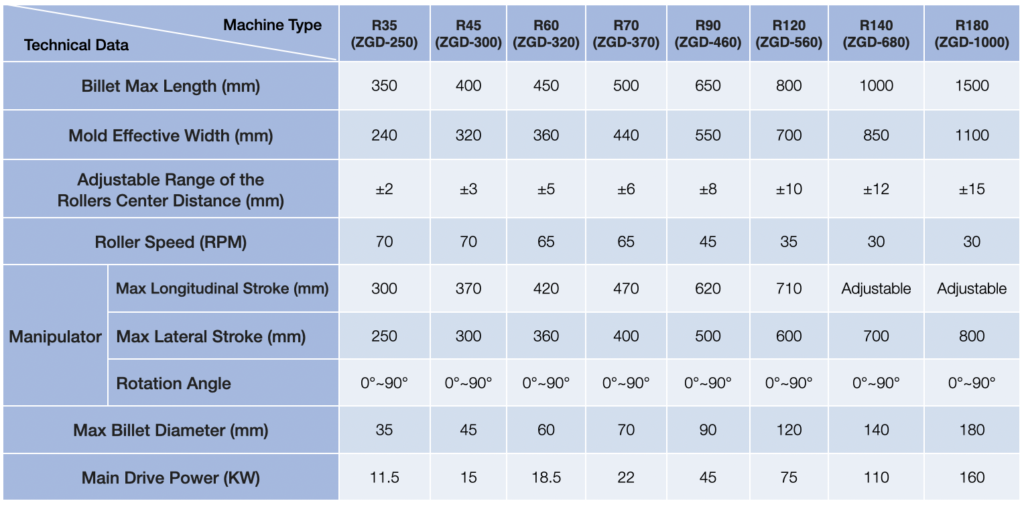

R70-500 Automated Roller For Solid Metal Preform:

- Heavy-Duty Use: Ideal for large component forging.

- High Precision: Ensures accuracy in dimensions.

- Energy Efficient: Reduces electricity consumption.

- User-Friendly Interface: CNC controls for simplified operation.

- Durable Design: Built to withstand the rigorous industrial environment