Smart Solution

to Replace Air Hammers

Automation

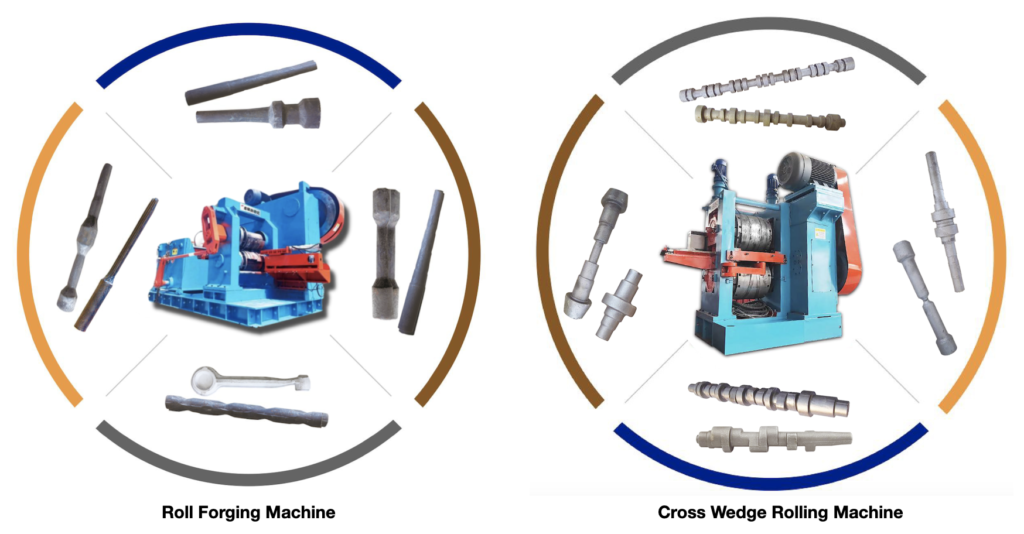

Roll Forging Machine

Manipulator Flexibly performs Solid Metal Billets.

Elevate Efficiency | Optimize Costs | Maximize Mold Durability

Traditional Air Hammer

Inconsistent Metal Shape

High Labor Cost

Material Wastes

Short Mold Lifespan

Automation Roll Forging

Consistency Metal Preforming

Automation Manipulator

Optimize Cost & Save Budget

Long Lifespan of Mold

Redefinig Metal Shaping

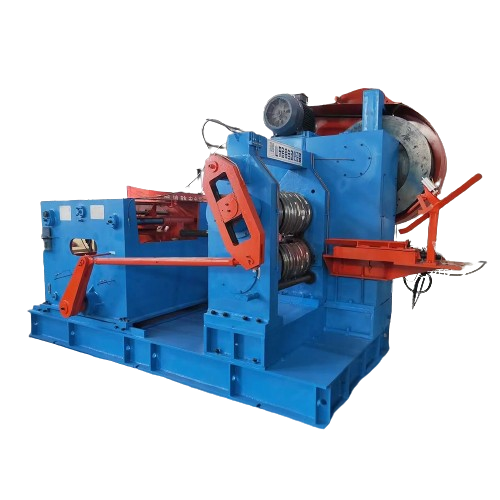

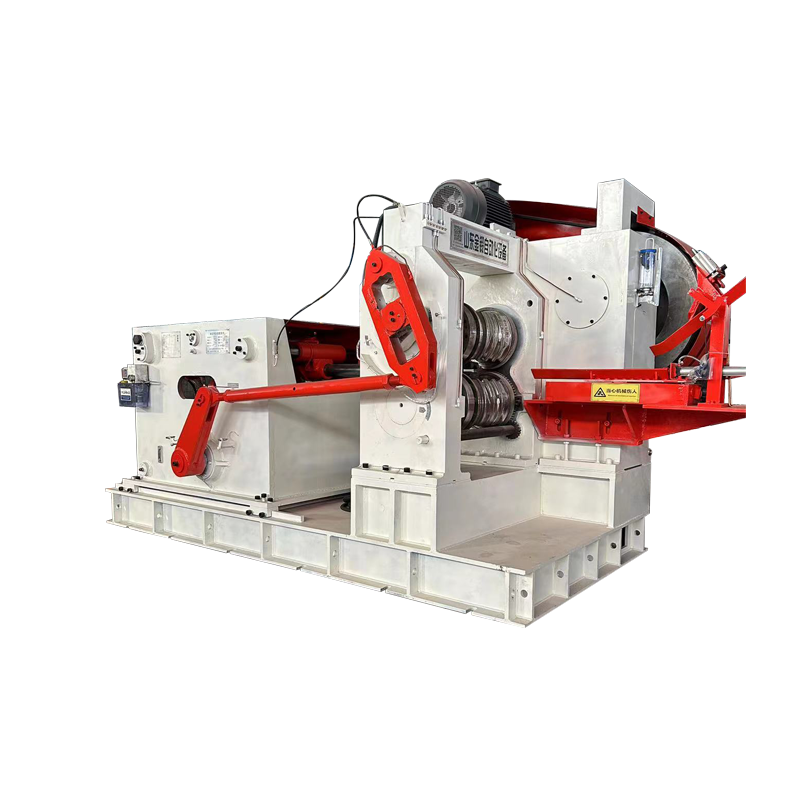

Universal Metal Preforming Forging Roll Machine

The roll forging machine is primarily designed for the elongation and preforming of arm-like or shaft-type metals, transitioning the diameter from thicker to thinner

- SmartFlex Manipulator

- Individual Mold (2 to 5 passes)

Application Range

Make Your Metal Pre-forming Easier & More Effective

Auto Swing Arm

Auto Gear Shaft

Auto Camshaft

Auto Connecting Rod

Lifting Riggings

Lifting Hook

Selector Fork

Tie Riggings

Hardware Tools

Suspension Arm

Auto Suspension Parts

Auto Steering Knuckle

Motorcycle Crankshaft

Bicycle Crank

Crankshaft of Textile Machine

Auto Control Arm

Your Benefits

Benefit 1

Automated Manipulator=Labor-Savings

An efficient alternative solution to air hammers or punching machines. Equipped with an advanced manipulator for feeding materials automatically, our machine minimizes reliance on manual skills and experience, and of course cuts down the labor requirements by at least 2 employees, freeing up your workforce for more critical tasks

Benefit 2

Significant Output Enhancement

Forget the old method of air hammer where you’d be happy to see output of 500pcs at the end of the day. With our roll forging tech, you’re looking at a leap of 1500-2000 pieces daily. This isn’t just an upgrade; it’s a complete transformation of how you operate, bringing you to the front of competitors in the forging industry.

Benefit 3

Unmatched Precision in Every Piece

Traditional methods like air hammers often leave you with varied shapes, leading to material waste and headaches in subsequent forging processes. Our roll forging technology delivers billets with unparalleled consistency, slashing waste and smoothing the path for the next steps in production. This precision not only cuts basic costs but also simplifies operations, making your entire process more efficient,

Benefit 4

Squeeze More Out of Every Kilogram

Traditionally, shaping a billet eats up 5kg of your precious material. Now, enter our roll forging machine: that number drops to just 4.5kg. It’s a revelation in material efficiency. With our technology, you’re not just cutting back on waste; you’re turning what used to be excess into extra profit. Imagine the impact over hundreds, thousands of billets? It’s about redefining efficiency in your forging operations

Benefit 5

Elevate Efficiency, Slash Costs

By eliminating unnecessary heating, our roll forging machine slashes your energy consumption and reduces furnace wear. Significant savings on your energy expenses and a boost in equipment longevity. You’re not just forging metal; you’re crafting a leaner, more profitable operation. With every heat cycle, you’re banking on efficiency that translates into real, tangible savings. It’s the smarter way to forge, ensuring your furnace works for you, not against your bottom line

Benefit 6

Maximize Mold Durability, Optimize Costs

Imagine firing up your forge and heating metal to a blazing 1100 degrees, only to see it efficiently pre-formed and cooled to 800 degrees, ready for the next stage. Now, think about your old air hammer process, where you’d be lucky to get 2000 pieces out of that heat. Time to shift gears! Our roll forging machine isn’t just another piece of equipment; it’s a revolution, churning out up to 8000 precision pieces from the same heat

The Story of QianLiMa Forging

Introduction:

QLM Forging Factory was established in 1987 and led by highly skilled and experienced two generations of technical engineers. We also have a professional technician team who are dedicated to assisting our clients in designing and manufacturing customized machinery that is tailored to their specific forging needs.

Products:

Primary products are roll forging machines and Cross wedge rolling machines, which are applied in producing metal billet preform. QLM machines are crafted with an eye for detail. Every single part, from the machine body to the basement, is meticulously worked on in a Gantry Machining center. This ensures every hole, every surface, is spot-on. What this means for you is equipment that’s not just precise, but also stable and durable, keeping your forging operations smooth and extending the life span of your tooling moulds. It’s all about giving you more bang for your buck and helping your budget stretch further in every possible way.

Application:

Rotary forging machines can be widely used in many forging industries, preforming parts and mold forging pieces. Such as automotive engine connecting rods, crankshafts, steering knuckles, tie rods, arm-type rod forgings, motorcycle forgings, hardware tools, aviation blades, lifting riggings, agricultural machinery forgings, cutlery, and medical instruments.

Advantages:

Moreover, our location has special advantages in combination with forging comprehensive services, because lots of local sources of accompanying machines, for example, metal heating systems, metal preform machines, electric screws press or servo-type direct drive press machines, pneumatic/hydraulic press machines, metal trimming machines. All your forging needs will be settled down one stop here in our city.

Automation

Forging Solution

Ready to optimize your forging process? Contact us today and our technical team will assist you with tailored forging solutions

Video Gallery

Watch how it works. Solution to Replace Air Hammers

Precision, Speed, and premium Quality. Revolutionize Forging with Reduce roller Machines.

Partners Worldwide

We pride ourselves on our commitment to quality, service and innovation.

Let’s start forging a lasting friendship together

Contact Us

Optimum Forging Solution and Budget Friendly.

Let’s connect!